Adani Green Energy Limited (AGEL) è una delle più grandi società che sviluppa, costruisce, possiede, gestisce e mantiene progetti per l’energia solare ed eolica in India, con un portafoglio progetti attuale di 13.990 MW. Angel è presente in 11 stati indiani attraverso i parchi eolici e/o solari e ha nel portafoglio 54 progetti operativi e 12 siti in costruzione, aiutando così l’India nel suo cammino verso le energie rinnovabili. Nell’ottica di una crescente politica Indiana rivolta alla decarbonizzazione, Angel ha stretto un accorgo strategico con Total, la quale ha rilevato il 20% di Angel, dopo la proficua collaborazione negli anni scorsi nell’area dei servizi di distribuzione del gas in India. Infatti nel 2018 Total aveva investito in Adani Gas che si occupava della gestione della distribuzione del gas nelle città. Total e Adani hanno concordato un investimento di 2,5 miliardi di dollari inerente ad asset solari già operativi pari a 2,35 GWac di proprietà di Angel e il diritto, da parte di Total, ad un posto nel consiglio di amministrazione della società. Angel, nel 2015, ha avviato il parco solare più grande del mondo, situato a Kamuthi, che produce 648 MW di energia e, ad oggi, detiene una produzione di circa 3 GW da energie rinnovabili, con altri 3 GW in costruzione e 8,6 GW in fase di sviluppo. L’obbiettivo dell’azienda è arrivare entro il 2025 con una produzione di 25 GW di energie rinnovabili. Per Total, l’accordo con Angel permetterà di raggiungere entro il 2025 la produzione lorda di 35 GWp con l’obbiettivo di incrementare tale capacità fi 10 GW all’anno. Vedi maggiori informazioni

SCOPRI DI PIU'

Partendo dall’epoca romana si arriva fino ai giorni d’oggi per capire come è cambiato l’approccio alla parità di genere di Marco ArezioUn lungo excursus di più di duemila anni, cercando di interpretare come la condizione della donna nella società, in famiglia e nel mondo del lavoro, sia cambiata, influenzata dal tempo che è passato, dalle conoscenze tecniche, dalle rivoluzioni culturali, religiose, economiche e sociali. Quello che interessa è cercare di capire se, trascorsi 2000 anni, la posizione della donna sia evoluta in meglio e quanto lo sia realmente. Può diventare comunque difficile fare una comparazione precisa, sull’importanza e sulla considerazione della donna nel contesto sociale, specialmente in determinate epoche e in determinati paesi, dove l’intervento di alcuni fattori importanti ne hanno condizionato il corso. In generale, la comparazione storica su un periodo così lungo ha un senso se teniamo in considerazione le popolazioni che hanno abitato il continente Europeo, di cui abbiamo maggiori tracce storiche e termini comparativi. La condizione delle donne nell'impero romano La condizione delle donne nell'Impero Romano, per quanto si possa pensare, poteva essere di libertà e considerazione per l’epoca, tenendo però presente alcuni fattori, come la classe sociale, l'età, la cittadinanza e il periodo storico. Status giuridico Nella legge romana, le donne erano viste come cittadine, ma non avevano gli stessi diritti politici degli uomini. Non potevano votare o detenere cariche pubbliche. Tuttavia, potevano possedere beni e ereditare proprietà. Pater familias La società era patriarcale, con il capo della famiglia che aveva potere assoluto sui membri della stessa, questo significava che le donne erano sotto la tutela legale dei loro parenti maschi per gran parte della loro vita. Matrimonio Il matrimonio era una parte fondamentale della vita delle donne romane. Queste, spesso, si sposavano in giovane età, e il matrimonio era visto principalmente come un mezzo per produrre eredi. Tuttavia, esistevano varie forme di matrimonio, alcune delle quali conferivano alle donne un grado maggiore di indipendenza e autonomia. Educazione Le donne di famiglie più agiate avevano accesso all'istruzione e potevano imparare a leggere, scrivere e studiare letteratura, anche se l'educazione superiore era riservata agli uomini. Vita quotidiana La qualità della vita quotidiana delle donne romane dipendeva dalla loro classe sociale. Coloro che appartenevano alle classi superiori avevano spesso schiavi o servitori che svolgevano i lavori domestici, mentre quelle delle classi inferiori lavoravano spesso nei campi, nei negozi o nelle case. Influenza culturale e religiosa Anche se le donne non avevano un ruolo ufficiale nella politica romana, avevano un'influenza significativa in altri aspetti della società. Ad esempio, c'erano sacerdotesse ed associate a vari culti che svolgevano libere pratiche religiose. La figura della "matrona", o nobile donna romana, era altamente rispettata e spesso idealizzata per la sua virtù e integrità. Evoluzione nel tempo La condizione delle donne variò nel corso del tempo durante l'impero romano. Si può infatti notare, in questo lungo periodo, un aumento dell'influenza e dell'autonomia delle donne, in particolare nelle classi superiori. Ad esempio, alcune imperatrici come Livia, Agrippina la Giovane e Faustina avevano un notevole potere e influenza. Possiamo quindi dire che, per le donne romane agiate, la condizione sociale e le libertà erano notevoli considerando che vivevano in una società patriarcale e militare. La condizione delle donne nel medioevo Caratterizzare la condizione delle donne nel Medioevo è un argomento vasto e complesso, poiché il periodo storico si estende per quasi mille anni e copre diverse regioni geografiche. Inoltre, la loro condizione variava notevolmente a seconda della classe sociale, della regione, dell'età e di molti altri fattori. Tuttavia abbiamo alcuni interessanti spunti comparativi tra l’approccio dell’epoca romana verso quello medioevale nella considerazione della donna. Ruoli tradizionali Nel Medioevo, le donne erano spesso associate a ruoli domestici e familiari. Si aspettava che si prendessero cura della casa e dei figli, senza grande distinzione tra contadini e nobili. Matrimonio Il matrimonio era una parte fondamentale della vita delle donne medievali, che era spesso organizzato per ragioni economiche o politiche, piuttosto che per amore, con l’importanza della della dote, un elemento essenziale per le unioni. Lavoro Mentre le donne erano principalmente legate al focolare domestico, molte lavoravano anche al di fuori della casa, spesso per necessità, ma difficilmente in posizioni di potere. Potevano essere coinvolte in mestieri come la tessitura, la birrificazione o la vendita al mercato. Educazione L'accesso all'istruzione era limitato, anche se esistevano eccezioni. Nei conventi, ad esempio, le donne potevano ricevere un'istruzione, ma la loro cultura era destinata a rimanere delle mura in cui vivevano, senza che potessero esercitare le loro conoscenze nella società. Religione In una società piuttosto ostile alle donne, i conventi offrivano una delle poche opportunità di ritirarsi dalla società tradizionale e ottenere un certo grado di indipendenza. Molte trovavano nei conventi un rifugio e un luogo di istruzione e devozione. Durante il Medioevo, ci furono anche molte donne sante e mistiche, come Santa Chiara d'Assisi o Ildegarda di Bingen, che ebbero un'influenza significativa. Legge Le donne medievali avevano anche molti diritti legali limitati. Erano spesso sottoposte all'autorità del loro padre o marito. Tuttavia, in alcune regioni e in speciali circostanze, potevano possedere beni, gestire attività o agire in tribunale. Variazioni regionali È importante sottolineare che la condizione delle donne variava notevolmente a seconda dell’area geografica in cui vivevano. Ad esempio, le donne nelle società scandinave medievali avevano diritti e opportunità significativamente diversi rispetto alle loro controparti nel sud dell'Europa. La condizione delle donne a cavallo delle due guerre mondiali Il periodo compreso tra la fine della Prima Guerra Mondiale e la conclusione della Seconda Guerra Mondiale fu cruciale per i diritti delle donne e per il cambiamento del loro ruolo nella società in molte parti del mondo. Questo periodo fu caratterizzato da significative evoluzioni politiche, sociali ed economiche, che hanno posto le basi per i futuri movimenti femministi. Ruolo nelle guerre Durante entrambe le guerre mondiali, molte donne entrarono nel mondo del lavoro per sostenere l'industria bellica e compensare la mancanza di mano d'opera maschile, che era al fronte. Questa situazione permise alle donne di dimostrare le proprie capacità in ruoli tradizionalmente maschili. Suffragio Dopo la Prima Guerra Mondiale, molte ottennero il diritto di voto in diversi paesi come riconoscimento del loro contributo nello sforzo bellico. Nel 1918, ad esempio, il Regno Unito concesse loro il diritto di voto a coloro che avevano un'età superiore ai 30 anni (e nel 1928 a tutte le donne adulte), e gli Stati Uniti ratificarono l'Emendamento 19 nel 1920, che garantiva alle donne il diritto di voto. Emancipazione economica La necessità di lavoratrici durante le guerre e la crescente urbanizzazione e industrializzazione, portarono molte donne a cercare lavoro fuori casa. Tuttavia, molte furono spinte fuori dal mercato del lavoro con il ritorno dei soldati al termine dei conflitti. Cambiamenti culturali Gli anni '20 del secolo scorso, in particolare, furono segnati da una notevole emancipazione culturale. Il simbolo della "flapper" negli Stati Uniti e in Europa rappresentava una nuova generazione di donne che sfidavano le convenzioni tradizionali, portando capelli corti, indossando abiti più corti, fumando e bevendo in pubblico, comportandosi in modo più liberale anche dal punto di vista sessuale. Legislazione sui diritti delle donne Molte nazioni introdussero legislazioni per proteggere e ampliare i diritti delle donne, compresi i diritti sul lavoro, i diritti riproduttivi e la protezione contro la discriminazione. Effetti della Seconda Guerra Mondiale La Seconda Guerra Mondiale portò nuovamente molte donne nel mondo del lavoro. Tuttavia, il dopoguerra vide anche un forte ritorno ai valori tradizionali, e molte donne furono incoraggiate a tornare ai ruoli domestici. La condizione delle donne ai giorni d'oggi La condizione delle donne ai giorni d'oggi varia notevolmente in base alla geografia, alla cultura, alla religione, all'economia e ad altri fattori. Tuttavia, rispetto al passato, ci sono state molte evoluzioni positive nel campo dei diritti delle donne e della parità di genere. Educazione La partecipazione delle ragazze all'istruzione è aumentata in molti paesi, e in alcune regioni le donne ora superano gli uomini in termini di successo educativo. Lavoro Anche se le donne sono più presenti nel mercato del lavoro rispetto al passato, la parità salariale rimane un problema in molte regioni. Queste sono anche sottorappresentate in posizioni di leadership e in certi settori, come la tecnologia e l'ingegneria. Violenza contro le donne La violenza domestica, l'aggressione sessuale e altre forme di violenza basate sul genere, rimangono problemi significativi a livello globale. Campagne come #MeToo hanno attirato l'attenzione su questi problemi, ma c'è ancora molto da fare per prevenirli e affrontarli. Diritti legali Mentre molte nazioni hanno fatto progressi nel riconoscere i diritti legali delle donne, esistono ancora leggi e pratiche discriminatorie in vari paesi che limitano l'autonomia, i diritti di proprietà e l'uguaglianza delle donne davanti alla legge. Influenza culturale e mediatica Le donne sono diventate figure più prominenti nei media, nell'arte, nello sport e in altri settori della società, anche se spesso devono affrontare stereotipi di genere e rappresentazioni sessualizzate. In conclusione, sebbene ci siano state molte evoluzioni positive nei diritti e nelle opportunità delle donne nel corso degli anni, esistono ancora numerose disuguaglianze e sfide che le donne devono affrontare in tutto il mondo. La lotta per la parità di genere e i diritti delle donne continua ad essere una questione centrale nel XXI secolo. Traduzione automatica. Ci scusiamo per eventuali inesattezze. Articolo originale in Italiano.

SCOPRI DI PIU'

La tecnica di recupero dei materiali preziosi nei rifiuti elettrici ed elettronici RAEEdi Marco ArezioDa tempo, il sistema della gestione e recupero dei rifiuti in Europa ha avviato un proficuo lavoro di riciclo degli scarti da post consumo, anche se con modalità e risultati differenti da paese a paese. In particolare le filiere più consolidate ad oggi sono quelle della carta, del vetro, del metallo, del legno e della plastica, da cui si ricavano annualmente ingenti risorse, in termini di materia prima seconda, che vengono impiegate nuovamente per la realizzazione dei prodotti. Basti pensare alla filiera dell’alluminio o del vetro che hanno un tasso di riciclo molto alto, permettendo di riutilizzare, in modo continuativo, il rifiuto nella produzione di articoli, minimizzando il ricorso alle materie prime naturali. Nel mondo dei rifiuti ci sono anche filiere di riciclo poco sviluppate, che presentano numeri di crescita potenzialmente molto alti e promettenti, dalle quali ci si attende un contributo sostanziale per il riciclo di preziosi elementi chimici che, diversamente, dovremmo estrarre dalla natura. Mi riferisco ai rifiuti elettrici ed elettronici, i materiali da costruzione, gli inerti, e altri materiali che possono contribuire in maniera importante a migliorare la critica situazione delle materie prime sul mercato internazionale. Alcuni metalli, per esempio, sono più difficili da trovare sul mercato e il loro costo è diventato quasi proibitivo, nello stesso tempo, non avendo sviluppato una filiera di recupero efficiente, vengono buttati in discarica. Un riferimento specifico al problema può essere rappresentato dai rifiuti RAEE, le cui percentuali di recupero dei componenti sono ancora abbastanza limitate, rispetto alle tonnellate di scarti che annualmente vengono buttate ogni anno nel mondo. All’interno dei rifiuti RAEE troviamo materie prime estremamente pregiate, come l’oro, l’argento, le terre rare e altri numerosi metalli che, per quanto estremamente preziosi, non sono facili da recuperare. Una via è quella di sottoporre i rifiuti elettrici ed elettronici, dopo la loro selezione e macinazione, alla cosiddetta idrometallurgia, un insieme di tecniche chimiche e chimico-fisiche, che permette l’estrazione dai rifiuti dei minerali preziosi da recuperare. Cosa è e come avviene il processo Idrometallurgico? Il processo Idrometallurgico si occupa del trattamento in fase liquida dei rifiuti elettrici ed elettronici, degli scarti industriali o di altre tipologie di rifiuti, finalizzate al recupero dei metalli presenti. Il processo può essere diviso in due fasi, per semplificare il processo:1. Liscivazione: consiste della dissoluzione del rifiuto da trattare attraverso l’impiego di una soluzione specifica, permettendo la dissoluzione dell’elemento solido e la stabilità dei componenti. 2. Separazione e purificazione del metallo: dal processo di lisciviazione si ricava una soluzione contenente ioni metallici e molte altre impurità. A questo punto può essere necessario trattare in maniera opportuna la soluzione (ad esempio tramite una filtrazione per rimuovere eventuali solidi sospesi, o variando alcuni parametri operativi, quali la temperatura o il pH della soluzione stessa), prima di procedere alle fasi successive del recupero del metallo. Le operazioni di recupero e purificazione possono essere completate tramite le seguenti fasi: • precipitazione/cristallizzazione • scambio ionico • estrazione con solvente • elettrodeposizione Per l’estrazione delle sostanze da recuperare si utilizza un solvente, attraverso una fase definita “estrazione liquido-liquido”, che è un processo per cui una fase liquida viene trasferita ad un’altra fase liquida ma non miscibili tra loro. Per realizzare questa operazione viene utilizzato un estraente, cioè una molecola avente proprietà complessanti che, reagendo secondo vari meccanismi con una sostanza disciolta nella fase acquosa, è in grado di estrarla. Queste due fasi, dissolvente ed estraente, costituiscono la fase organica, le cui peculiarità sono: • l’alta selettività che permette quindi la separazione di metalli con proprietà molto simili • possibilità di trattare scarti e residui industriali • elevati fattori di separazione che consentono di ottenere prodotti con un grado di purezza estremamente elevato • impiantistica semplice, flessibile e facilmente automatizzabile • impianti con impatto ambientale contenuto (i solventi sono continuamente riciclati e si opera prevalente-mente a temperatura ambiente) • basso consumo energetico • possibilità di trattare matrici contenenti basse concentrazioni di metalli per i costi di processo contenuti.Categoria: notizie - idrometallurgia - economia circolare - riciclo - rifiuti - metalli - rottame

SCOPRI DI PIU'

Trasporto via Mare: Cosa ci Dobbiamo Aspettare per la Fine del 2021?di Marco ArezioLe tariffe raggiunte per il trasporto dei containers via mare continuano a macinare record su record, con nuovi picchi dei prezzi sulle rotte Asia-Europa-AmericaDopo il periodo di punta della pandemia mondiale, il forte rimbalzo della domanda dei beni di consumo ha messo in crisi il sistema, imprimendo una forte pressione sia gli spedizionieri che i produttori. Sembra pazzesco anche scrivere i dati sui costi dei container che, sulla linea Asia-Europa, sono arrivati a toccare i 18.000 USD, mentre sulla rotta Asia-Stati Uniti addirittura 22.000 USD, secondo i dati riportati da Freighttos. E’ forse bene ricordare che prima del periodo pandemico i costi per gli stessi servizi si aggiravano intorno ai 3.000 USD. Tra le cause di cui abbiamo parlato in questi mesi attraverso diversi articoli, si può evidenziare che le famiglie, tra il periodo pandemico e post pandemico, hanno cambiato i loro stili di vita, riducendo le spese per viaggi e ristoranti, ed incrementando l’acquisto di mobili, elettrodomestici ed oggetti per la casa. Questi cambiamenti hanno modificato l’approccio alla spesa, creando una fortissima domanda di beni, soprattutto dalla Cina verso l’Europa e gli Stai Uniti, con la conseguente incredibile ascesa di richiesta di containers per il trasporto di tutta questa merce. Di conseguenza, le compagnie di navigazione, prese alla sprovvista, non sono riuscite a soddisfare tutta la richiesta crescente, complice anche le problematiche metereologiche straordinarie durante l’inverno negli Stati Uniti e il blocco temporaneo del canale di Suez. Per questi motivi, se guardiamo verso l’ultima parte dell’anno, la situazione dei costi dei trasporti marittimi non fà sperare in una diminuzione a breve, in quanto gli importatori si stanno approvvigionando per il periodo Natalizio e del Ringraziamento e sono disposti a sostenere questo incredibile onere per non compromettere le vendite di fine anno. Il problema che devono affrontare le aziende che si occupano di import & export non riguarda solo la situazione dei costi finanziari enormi, per unità venduta a causa dei costi della logistica, ma anche ai numerosi ritardi continui e prolungati per la consegna degli ordini.

SCOPRI DI PIU'

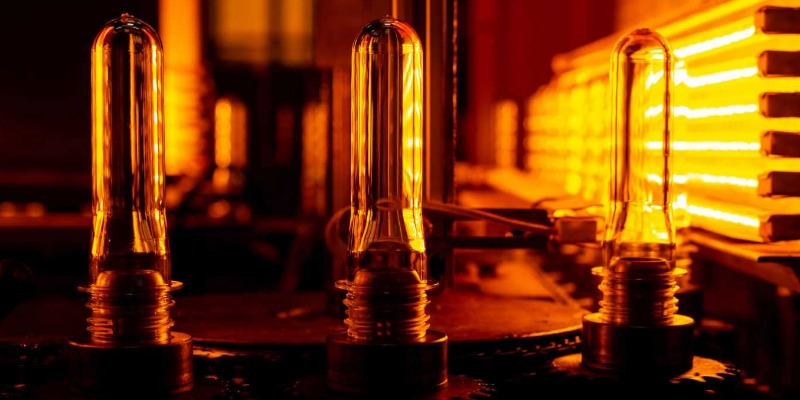

Trasparenza, resistenza meccanica, effetto barriera possono variare, modificando il grado di cristallinitàdi Marco ArezioAbbiamo affrontato, in articoli precedenti, alcuni aspetti importanti nell’utilizzo del PET per la produzione di manufatti, come la viscosità e il peso molecolare o i principali fenomeni di degradazione del PET. In questo articolo vediamo un altro aspetto centrale, che riguarda la gestione del grado di cristallinità del PET e come, il suo variare, può influenzare molti fattori strutturali, come la trasparenza dei manufatti, gli aspetti strutturali e meccanici e l’effetto barriera verso i componenti che il prodotto conterrà. Per entrare subito in argomentazioni tecniche, possiamo dire che il PET è un polimero semicristallino, questo vuol dire che la sua struttura solida è costituita da una fase amorfa, in cui le macromolecole che lo costituiscono sono disposte in gomitoli statici, e da una fase cristallina, in cui le catene si dispongono in una forma geometrica precisa. Detto questo, possiamo notare come il PET sia un polimero che possa essere sottoposto alla cristallizzazione, ma, come tutti i polimeri, non la raggiungerà mai completamente a causa della natura stessa delle macromolecole che lo compongono ed alla loro irregolarità. Le catene, infatti, tendono a disporsi verso minime distanze intermolecolari, in quanto il principio generale che regola l'aggregazione delle macromolecole per la formazione di una struttura cristallina è la creazione di interazioni inter e intra-catena, attraverso regolarità degli angoli torsionali della macromolecola. Il rapporto tra le due fasi dipende da molti fattori, come le caratteristiche intrinseche del materiale e i processi termici che ha subito. Durante la fase di cristallizzazione del PET le macromolecole formano una struttura lamellare, in cui le catene si ripiegano su sé stesse in modo ordinato, ma, nello stesso tempo si verifica la creazione di zone esterne disordinate. Il PET, essendo formato da queste due fasi, si dispone e si organizza in domini, in cui le due fasi coesistono, creando un limite massimo di cristallizzazione termica del 50-60% e, in certi casi, occorre utilizzare degli agenti nucleanti per raggiungere il valore limite.Ricordando che la cristallizzazione non ottimale dei polimeri può portare ad una certa opacità dei manufatti, possiamo dire che il PET ha una bassa velocità di cristallizzazione e, per questo, unite ad altre proprietà, ha avuto una rapida diffusione del mondo del packaging. Durante la lavorazione del PET, il picco di cristallizzazione si può raggiungere ad una temperatura di circa 160 - 170 °C, ma esiste anche una altro sistema per raggiungere questa fase, che è quella meccanica. Infatti, con le operazioni di stiro meccaniche ad una certa temperatura, si crea una cristallizzazione indotta, che consiste in una orientazione forzata delle macromolecole nella direzione dello stiro. Nell’orientazione uniassiale, in cui lo sforzo è applicato in un’unica direzione, si formano strutture dette fibrille, in quella biassiale, in cui lo sforzo ha due componenti perpendicolari tra loro, si formano cristalli larghi e piatti (plates).Questo fenomeno è influenzato da quattro fattori principali: - L’entità dello stiro - La velocità dello stiro - La temperatura - Il peso molecolare La combinazione di queste quattro entità determinano le caratteristiche del PET e, di conseguenza la qualità dello stesso, così, per definire un parametro che possa caratterizzare il prodotto in seguito a queste combinazioni, viene utilizzato un indicatore definito in ”grado di cristallinità”, con cui si vuole indicare la percentuale di materiale che si trova in fase cristallina rispetto alla quantità totale presa in considerazione. In particolare, un aumento del grado di cristallinità comporta un maggiore impaccamento e, grazie alla presenza dei domini cristallini che fungono da nodi fisici del reticolo, vi è un miglioramento delle proprietà meccaniche.Nello stesso tempo, come abbiamo già avuto modo di dire, un aumento della cristallinità del prodotto, può portare ad una certa opacità dello stesso, a causa dei diversi indici di rifrazione, infatti, questo deve essere preso in seria considerazione se si vogliono produrre delle bottiglie trasparenti. Ma dobbiamo anche prestare attenzione alla dimensione dei cristalli, infatti, due contenitori con lo stesso grado di cristallizzazione possono avere trasparenze od opacità differenti, così, più grandi saranno i cristalli, maggiori possibilità si avranno di produrre flaconi opachi. Alla cristallizzazione per stiro è legato il fenomeno di strain hardening, che comporta un aumento delle proprietà meccaniche, termiche e della resistenza a barriera del polietilentereftalato, determinando il successo nella produzione di contenitori.Il punto che individua l’inizio di tale fenomeno è definito Natural Stretch Ratio (NSR). Di conseguenza, quando si soffia una preforma, si deve raggiungere un grado di deformazione (rapporto di stiro) uguale o di poco superiore al NSR, per poter avere l’aumento delle proprietà necessarie per ottenere un prodotto leggero e conformante.Un altro fattore importante da tenere in considerazione durante il soffiaggio delle preforme, che incide sulla cristallizzazione del materiale, è la presenza di acqua. Infatti, se il contenuto di acqua nel PET può teoricamente arrivare all’1% del suo peso, bisogna considerare che la sua presenza può variare le proprietà fisiche, meccaniche e di barriera. Questo si verifica perché l’acqua è un plasticizzante che ha effetto sull’orientamento del materiale, sulla stabilità termica e, quindi, anche sulla cristallizzazione indotta per stiro, creando una situazione di scorrimento tra le macromolecole, riproducendo una similitudine con un polimero di viscosità inferiore. La percentuale di acqua influisce anche sul natural stretch ratio e, quindi, sulle proprietà del manufatto finito, a parità di stiro assiale e radiale, una preforma contenente acqua avrà proprietà inferiori, come se fosse soffiata a una temperatura più alta. Traduzione automatica. Ci scusiamo per eventuali inesattezze. Articolo originale in Italiano.

SCOPRI DI PIU'